In the USA, broiler chickens produce about 10-15 million tons of manure annually. Fresh poultry manure contains about 75% moisture that must be reduced prior to storage and land application. High moisture manure can lead to higher transport costs, faster reproduction of pathogens/bacteria and flies, and the generation of odors. Furthermore, wet manure tends to lose a higher ratio of nitrogen (N) as moisture plays a key role in the generation and emissions of ammonia (NH3) from chicken manure. Besides broiler chickens, USA has about 300 million laying hens. A commercial layer house with 100,000 hens usually produces 1,500 to 2,000 tons of manure every year. Currently, the primary fresh manure drying methods on commercial laying hen farms include manure belt drying with exhaust fans, manure drying tunnel or shed, air duct heating, and in-house composting (high-rise layer houses). Therefore, different manure drying methods have been innovated in the past years (Figure 1).

Figure 1. Poultry manure drying systems (photo credit: VDL Agrotech).

Manure Belt Drying System

Manure belts coupled with exhaust fans is a common method in conventional battery cage houses and cage-free houses (Figure 2). The manure belts are run every 3-4 days in order that the fresh manure will have a chance to dry within the laying house prior to storage within a manure storage facility. In summer, manure can be dried by reducing the moisture content from 75% to 20-30% over a 3 to 4 day period. However, manure drying is more difficult during winter weather due to weather-related reduction of house ventilation (e.g., manure moisture could still be 60-65% after 3 to 4 days in the laying hen house). Besides seasonal changes, another factor affecting manure moisture and drying efficiency is feed formulation. Some egg farms add salt to the feed to address pecking and bullying issues within a flock. Increasing salt content in the feed will increase manure moisture content from the resulting higher water intake of the layers.

Figure 2. Layer house manure belt system (photo credit: Chai).

Manure Drying Tunnel or Drying Shed

Considering that fresh manure will need a longer time to be dried under winter ventilation conditions, some layer farms are using a manure drying tunnel (Figure 3). After the manure is removed from the house, it is distributed evenly on a multi-tiered conveyer system. The manure passes through the tiers and is dried by either the exhaust fans of the layer house or additional fans installed specifically for the drying tunnel.

The drying speed of manure is correlated to the number of tiers and fans and can be calculated based on manure mass weight, volume (surface area and thickness), exhaust air temperature and relative humidity (RH), ambient air temperature and RH (if the manure drying shed is using a separate ventilation system instead of layer house exhaust fans), and manure temperature and moisture content before and after drying.

Figure 3. Manure drying tunnel on a layer farm. (photo credit: Ni et al., 2010; Chai et al., 2012; Big Dutchman).

In-House Air Duct Heating on Manure Belt

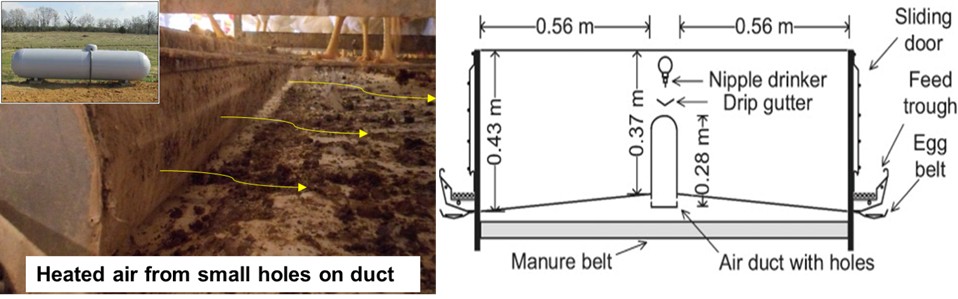

Building a manure drying tunnel or separate storage shed requires extra space and investment. Another option of expediting the drying of manure is air duct heating on the manure belt. Cage-free farms in the Midwest, for instance, may need to use an additional heating system to warm the layer house in winter due to lower bird density compared to conventional cage systems. The warm air can be introduced into the house through a duct above the manure belt (Figure 4). In that way, the manure can be dried to 10-20% after 3 to 4 days in the layer house during cold weather.

Figure 4. In-house air duct heating on manure belt (photo credit: Zhao et al., 2013).

However, this method requires the installation of extra equipment such as an air duct above each manure belt. Installing air ducts above belts to expedite the manure drying speed was reported in a few case studies in cage-free houses. More studies are needed to address how many holes are needed, hole size, and optimum air temperature and speed over fresh manure.

Summary

Manure drying with exhaust air has been extensively used in conventional battery cage and cage-free houses. For high-rise layer houses, in-house windrowing can reduce moisture within the manure pit. For cage-free houses, removing the litter floor or adding new bedding materials periodically on the top of litter can keep the floor dry. It can be challenging to dry manure efficiently in the winter due to reduced house ventilation and cold ambient temperatures. Manure drying tunnels/sheds or in-house air duct heating may help expedite the drying process. However, the space/land requirement and cost of construction and operation of manure drying tunnels/sheds or duct heating systems may prevent farms from implementing these practices. USDA support for implementation of new technology within agricultural systems can be found in programs such as the USDA Rural Energy for America (REAP) & the NRCS Environmental Quality Incentives Program (EQIP) programs. These programs offer financial incentives and cost-share funds to offset the costs of implementation of new equipment. These government programs are in place to assist producers in upgrading equipment and technology to be more environmentally sustainable.

USDA Rural Development – Rural Energy for America (REAP) programs:

https://www.rd.usda.gov/programs-services/all-programs

Further readings:

Chai, L., Ni, J.Q., Diehl, C.A., Kilic, I., Heber, A.J., Chen, Y., Cortus, E.L., Bogan, B.W., Lim, T.T., Ramirez-Dorronsoro, J.C. and Chen, L., 2012. Ventilation rates in large commercial layer hen houses with two-year continuous monitoring. British Poultry Science, 53(1), 19-31.

Chai, L., Xin, H., Wang, Y., Oliveira, J., Wang, K., & Zhao, Y. 2019. Mitigating particulate matter generation in a commercial cage-free hen house. Transactions of the ASABE, 62(4), 877-886.

Ni, J. Q., Diehl, C. A., Chai, L. L., Bogan, B. W., Cortus, E. L., Lim, T. T., & Heber, A. J. 2010. National air emissions monitoring study: emissions data from two manure belt layer houses in Indiana-site IN2B. Final Report, Purdue University, West Lafayette, IN.

Zhao, Y., Zhao, D., & Xin, H. 2013. Characterizing manure and litter properties and their carbon dioxide production in an aviary laying-hen housing system. In 2013 Kansas City, Missouri, July 21-24, 2013. American Society of Agricultural and Biological Engineers (ASABE).