Ammonia Issues in Poultry Houses

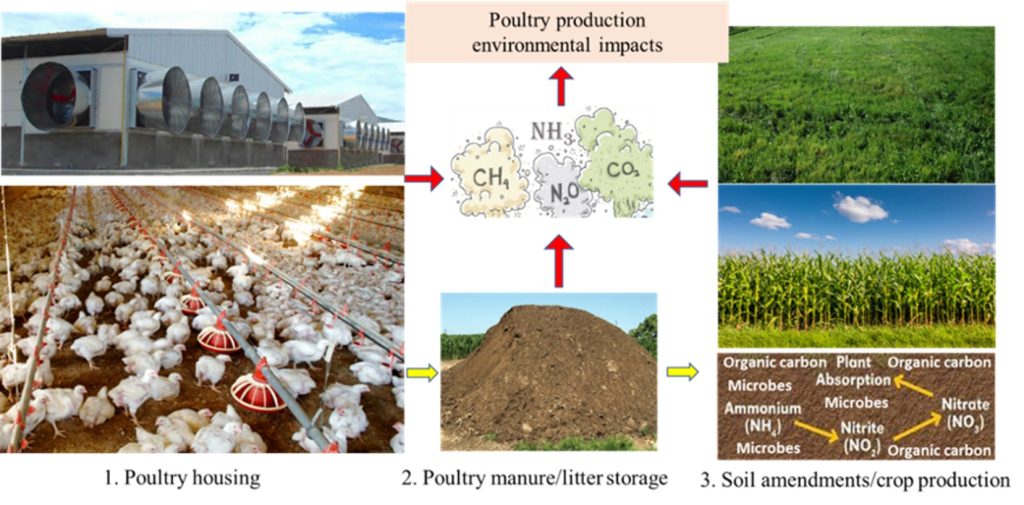

Confined animal feeding operations are the main sources of air pollutants such as ammonia (NH3) and greenhouse gases. Among air pollutants, NH3 is one of the most concerned gasses in terms of air quality, environmental impacts, and manure nutrient losses. It is recommended that NH3 concentrations in the poultry house should be controlled below 25 ppm. Otherwise, the health and welfare of animals and their caretakers will be impaired. After releasing from poultry houses, NH3 contributes to the form of fine particulate matters in the air and acidify soil and water bodies after deposition. Therefore, understanding the emission influential factors and impacts is critical for developing mitigation strategies to protect animals’ welfare and health, environment, and ecosystems. The primary NH3 emission stages include poultry housing, manure storage, and land application (Figure 1). Housing state usually contributes most of emissions. The influential factors for poultry housing include seasonal changes, feed management, bedding materials, animal densities, and animals’ activities.

Figure 1. Air emissions from poultry production systems.

It’s been proved that a higher level of NH3 (e.g., >25 ppm) results in lower production efficiency and poor welfare and health, e.g., respiratory disorder, less feed intake, lower growth rates or egg production, poor feed use efficiency, increased susceptibility to infectious diseases, and mortality. In addition, the egg quality (e.g., albumen height, pH, and condensation) was reduced after laying hens chronically exposed to high NH3 levels. High NH3 levels have detrimental effects on farm workers’ health as it is a corrosive substance to eyes, skin, and respiratory tract, and thus may cause irritation (throat, nose, eyes), and lung illness. Therefore, it’s critical to control NH3 levels in poultry houses.

Poultry House Ammonia Emission Processes

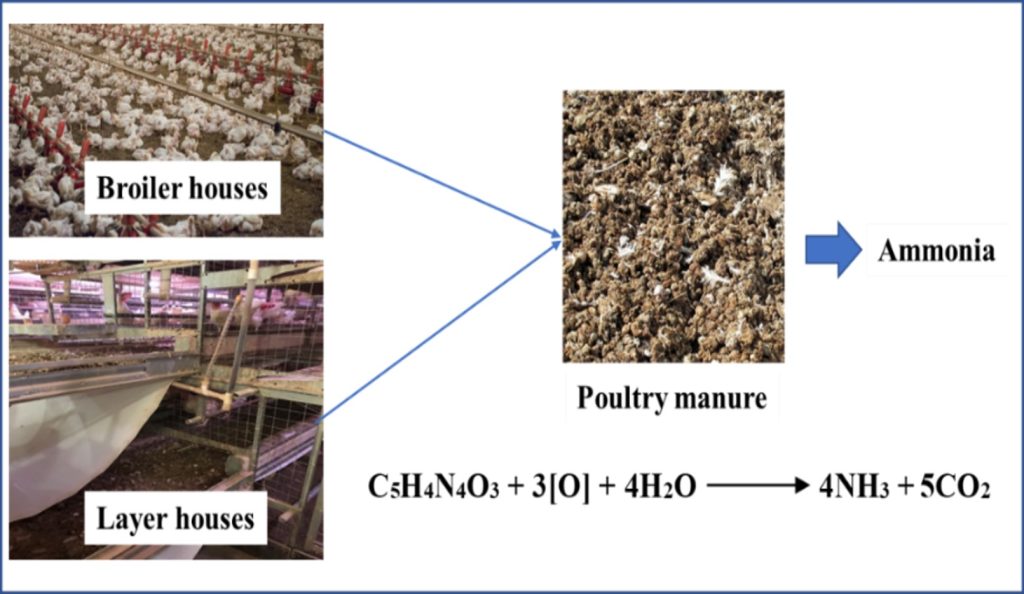

Prior to designing mitigation strategies, we need to understand NH3 generation processes. Ammonia gas is produced from microbial decomposition of nitrogen-containing substances like manure (feces and urine) and litter. Nitrogen found in animal feces is mainly unabsorbed protein and uric acid (poultry) or urea (mammals). Unabsorbed protein and uric acid are the two primary nitrogen components found in poultry feces contributing 70% and 30% of total nitrogen, respectively. Once excreted, nitrogen in excreta present in the form of urea (4-12%), uric acid (40-70%), and nitrogen of feed protein (10-40%) are quickly hydrolyzed to form NH3 through a series of microbial degradation in the presence of microbial enzymes in the manure (Figure 2).

Figure 2. Process of NH3 production from poultry houses.

Emissions influence factors and Mitigation Strategies

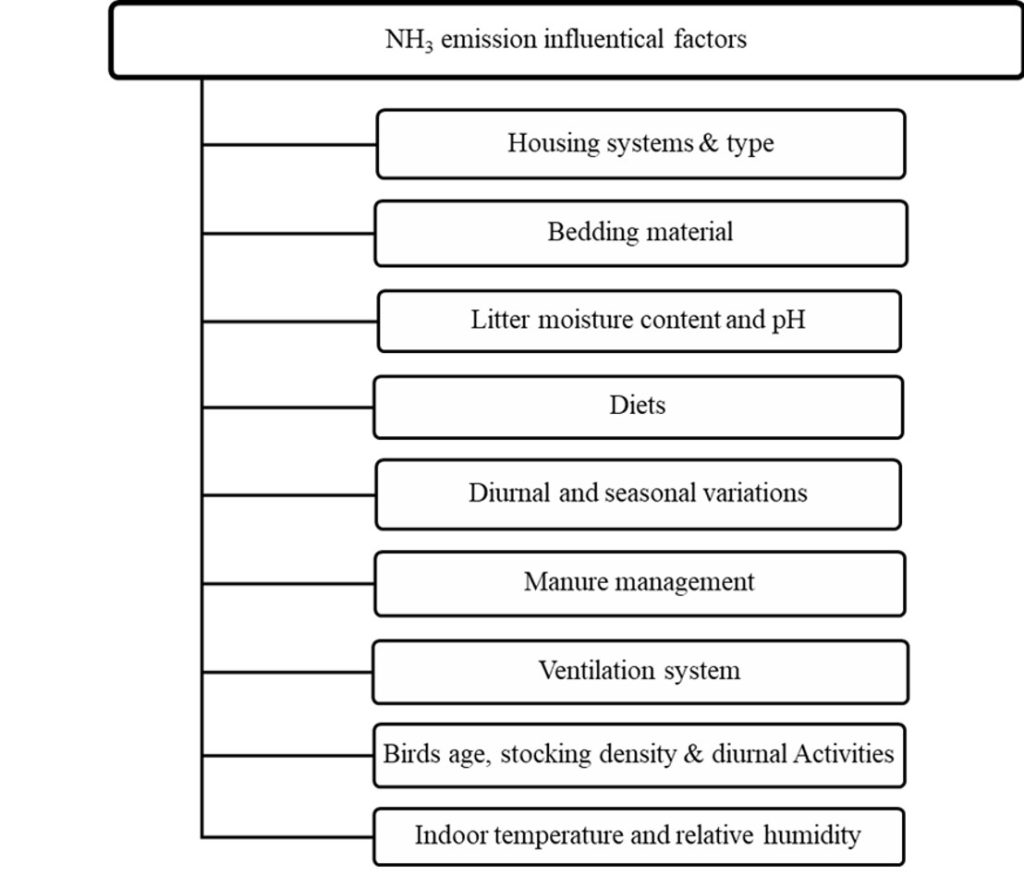

Ammonia emissions in poultry houses can be affected by climatic circumstances, geographical location, and the wide variety of management strategies. Emission influential factors can differ dramatically from one operation to another due to differences in diets, housing systems, and management procedures (Figure 3). Housing and management factors including housing style, bird density, litter conditions, handling methods, and ventilation rate are reported critical to indoor NH3 levels. In addition, indoor environmental parameters such as temperature, relative humidity, manure/litter pH level, air velocity can be correlated to the NH3 emissions directly or indirectly.

Figure 3. Key influential factors for NH3 generations in poultry houses.

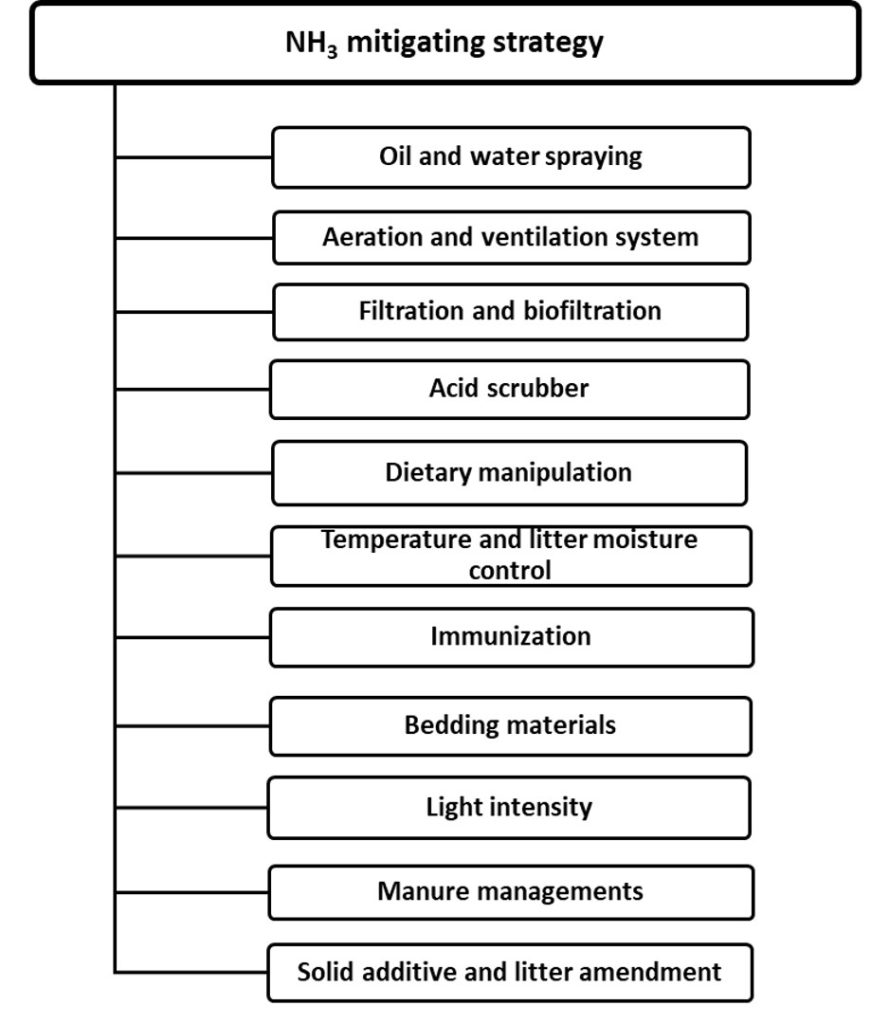

There are two primary approaches to control ammonia levels in animal houses: pre-excretion (i.e., reduction at the source before manure is produced, e.g., diet manipulation and feed additive) and pre-release (i.e., removal from the flow of gases before dispersing in the environment, e.g., litter additives, management, and new house design). Based on their working principles, mitigation technologies can also be divided into microbiological, biochemical, chemical, managerial, physical, and physiological methods, elaborated in Figure 4. For controlling poultry house NH3 levels and emissions, we analyzed various mitigation strategies such as litter additives, biofiltration, acid scrubber, dietary manipulation, bedding materials. Litter additives were tested with 50% efficiency in broiler houses and 80-90% mitigation efficiency for cage-free hen litter at a higher application rate (0.9 kg/m2). Filtration systems such as multi-stage acid scrubber have up to 95% efficiency on NH3 mitigation. However, cautions should be paid as mitigation strategies could be cost prohibitive for farmers, which needs assistances or subsidies from governments.

Figure 4. Overview of NH3 mitigating strategy in poultry houses.

Summary

Common animal production and health concerns as caused by long term high NH3 exposure (e.g., >25 ppm) include low broiler growth rates, burning of skin and eyes, and infections in respiratory system. In the worse situation (e.g., NH3 level > 200 ppm), animal mortality will increase. For controlling NH3 levels, various mitigation strategies, including biochemical, chemical, managerial, physical, and physiological practices, were analyzed, compared, and discussed. For instance, using litter additives to control NH3 is a common method in broiler chickens’ houses, which has yet to be used in cage-free hen houses, an emerging housing system transited from conventional cage systems due to public concern on animal freedom. However, ammonia mitigation strategies could be cost-prohibitive and thus need government assistance programs to facilitate sustainable poultry production.

Further reading:

Bist, R. B., Subedi, S., Chai, L., & Yang, X. (2023). Ammonia emissions, impacts, and mitigation strategies for poultry production: A critical review. Journal of Environmental Management, 328, 116919. https://doi.org/10.1016/j.jenvman.2022.116919